T3 T4 T04E Universal Turbo Stage III+Wastegate+Turbo Intercooler+piping 10PC Kit

Application:

Universal Turbo Kit Perfect For 1.5L-3.0L engine

This Kit Will be able to add 350+HP at 7.5-14.5 PSI.

(You will need Turbo Manifold, Modification and other accessories to complete the Turbo Kit Project)

*Notice:Please confirm that your vehicle displacement is 1.5L-3L before purchasing. Otherwise, if you buy the wrong one, you will not be able to use it normally.

Specification

Turbine Side:

Exhaust Inlet Flange: T3 T4 4 bolt Flange Patterns

Exhaust Outlet pipe Flange: 5 bolt Flange

Turbine Trim: 74.2

Turbine Inducer Diameter: 64.8 mm

Turbine Exducer Diameter: 55.8mm

Turbine A/R: 0.63

Compressor Side:

Compressor Trim: 48.1

Compressor Inducer Diameter: 52.7mm

Compressor Exducer Diameter: 76 mm

Compressor A/R: 0.5

Compressor Inlet Diameter: 72mm(2.8")

Compressor Outlet Diameter: 53mm(2")

Bearing Type: Wet Float Bearing

Cooling Type:Oil Cooling

Thrust Bearing:270 degree

Horsepower:Up to 400HP

Oil Inlet: 1/8 NPT

Turbo Type:Individual

Condition: Brand New

Accessories: You will get exactly as shown as picture above

Other specification in the kit :

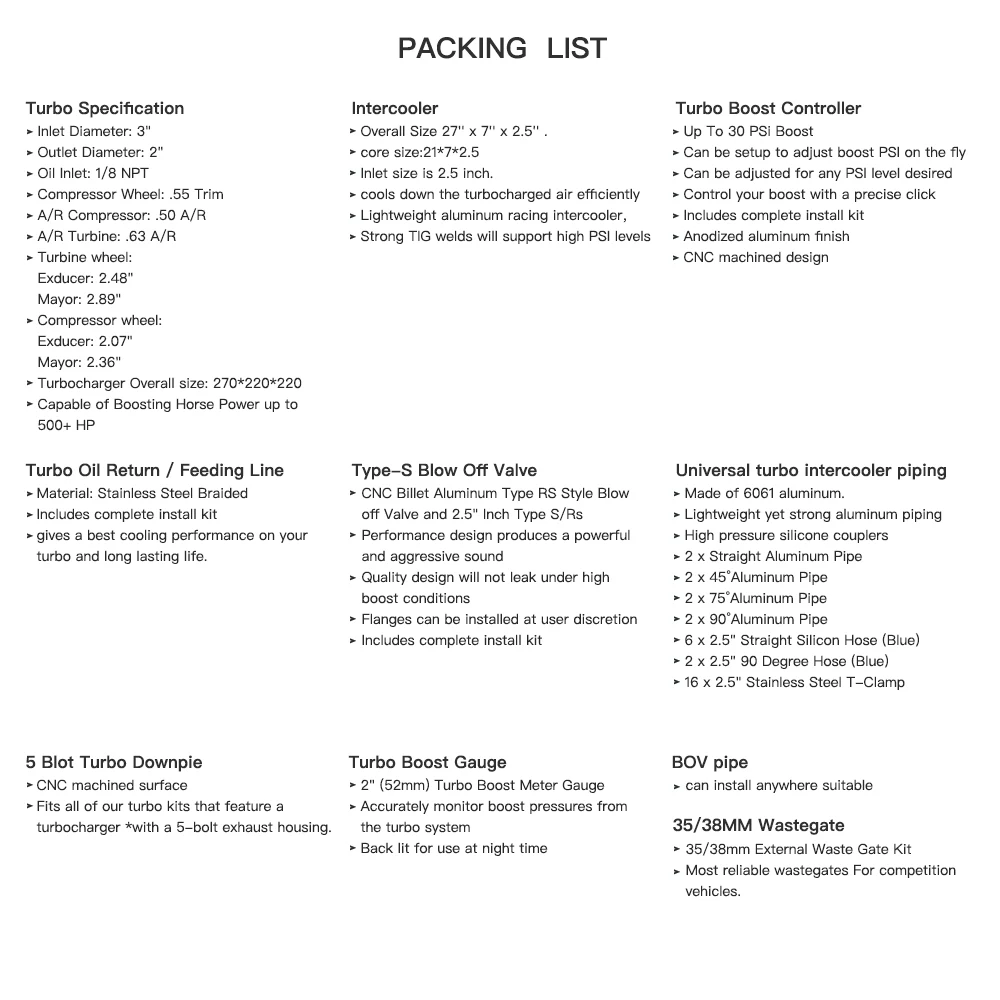

*1 x Intercooler: Size 27'' x 7'' x 2.5'' inch. Inlet size is 2.5 inch.

Support up to 350 hp for this small intercooler size - tube and fin style .

Intercooler core size: 21*7*2.5

*1 x Universal turbo intercooler piping kit including:

2 x Straight Aluminum Pipe

2 x 45°Aluminum Pipe

2 x 75°Aluminum Pipe

2 x 90°Aluminum Pipe

6 x 2.5" Straight Silicon Hose (Blue)

2 x 2.5" 90 Degree Hose (Blue)

16 x 2.5" Stainless Steel T-Clamp

*1 x Type-S Blow Off Valve: 2.5" Inch Type S/Rs Flange Pipe. 25PSi Boost!(Random Color)

*1 x BOV pipe: can install anywhere suitable

*1 x 35/38MM Wastegate: 35/38mm External Waste Gate Kit (the color will be shipped randomly(black/blue))

*1 x Turbo Boost Gauge: 2" (52mm) Turbo Boost Meter Gauge.

*1 x Turbo Boost Controller:

*1 x Turbo Oil Return / Feeding Line Kit: Turbo Oil Feed + Return Drain Line Kit Combo.

*1x 5 Bolt pipe: 2.5" t3/t4 5-bolt stainless steel TIG welded pipe. pipe length: 13“

Package Size:94x 46 x 45 cm

Package Weight: 24600g

Feature

1.Turbo charger:

*Turbine housing :Ductile iron QT450-10 - temperature resistant up to 700℃

*Steel turbine wheel:K418 alloy - high oxidation stability and resistance up to 900℃

*Compressor housing:ZL104 aluminum with lightweight

*Compressor wheel/blades:Cast aluminium blades – superior air tightness & corrosion resistance

*Product Performance

Cost-effective turbo increase 20-40% power for your car

Rich experience in turbo production and own factory

High-Speed oil seal ring and Precision clearance

Built for durability and strength

* Technology Advantage:

balancing Test by TURBOTECHNICS VSR3

G3-min-Flow VNT Turbo testing

Advanced Actuator Tester/Programmer

2. Intercooler

* core size:21*7*2.5 cools down the turbocharged air efficiently

* Lightweight aluminum racing intercooler,

* Strong TIG welds will support high PSI levels

3.Boost controller

* Can be setup to adjust boost PSI on the fly

* Can be adjusted for any PSI level desired

* Control your boost with a precise click

* Includes complete install kit

* Anodized aluminum finish

* CNC machined design

4. Intercooler piping kit

* Made of 6061 aluminum

* Lightweight yet strong aluminum piping

* High pressure silicone couplers and T-bolt clamps

5. Turbo Oil returen /Feeding line kit

* Stainless Steel Braided

* Includes complete install kit

* It helps circulate oil from the turbo charger to the oil pan.

* The kit provides a anodized look

* gives a best cooling performance on your turbo and long lasting life.

6.Blow Off Valve Kit

* CNC Billet Aluminum Type RS Style Blow off Valve

* Easy Mount Piping Set Included For Bolt-On.

* Including all necessary hardwares.

* easily adjustable to prevent both permature boost leakage and compressor surge.

* Fast response One For Low And High Boost Pressure.

* Performance design produces a powerful and aggressive sound

* Quality design will not leak under high boost conditions

* Flanges can be installed at user discretion

7. 38MM Wastegate

* Most reliable wastegates For competition vehicles.

* accurate boost control

* high quality appearance features Dual port design

* comes with waste gate spring (fully adjustable, up to 15 psi), allow you to add the spring to get desired high psi.

8. 5 Blot Turbo pipe

* CNC machined surface

* Fits all of our turbo kits that feature a turbocharger with a 5-bolt exhaust housing.

9. BOV pipe/Adapter

* can install anywhere suitable

10.Turbo Boost Gauge

* Red LED Illuminated Needles.

* Comes with All the Wiring Necessary for Installation.

* All Accessories are Included for Installation.

* Accurately monitor boost pressures from the turbo system

* Back lit for use at night time

Note

* Replace, repair or reconnect air cleaner element per manufacturer's manual to avoid compressor wheel damage.

* Make sure the oil drain line is lower than the turbo itself.

* Ensure exhaust outlet are well sealed by welding

* The degree of modification of the universal turbo depends on your individual vehicle.Professional installation is highly recommended.

* This Turbo is not vehicle specific. Please check the specifications and verify compatibility prior to placing your order.

* Before installing the new turbocharger, the cause that led to the failure of the turbo must be analyzed and eliminated (e.g. insufficient oil supply, foreign bodies in the intake area, crankcase ventilation without function, etc.)!

* Need modifications - Professionals ONLY (This is an aftermarket universal turbo kit for DIY purpose, and it's recommended to advanced players but not for beginners. )