Power Saws: Precision Cutting for Every Project

Top Power Saws for Professionals and DIY Enthusiasts

High-Performance Blades, Cordless Options, and Adjustable Speed

Perfect for Woodworking, Construction, and Home Improvement Projects

Durable and Reliable Power Tools for All Cutting Needs

Ergonomic Design, Safety Features, and Easy-to-Use

Get the job done right with our range of power saws, designed for precision cutting in a variety of projects. Whether you need a circular saw for fast, accurate cuts, or a jigsaw for intricate designs, we have the perfect tool for your needs.

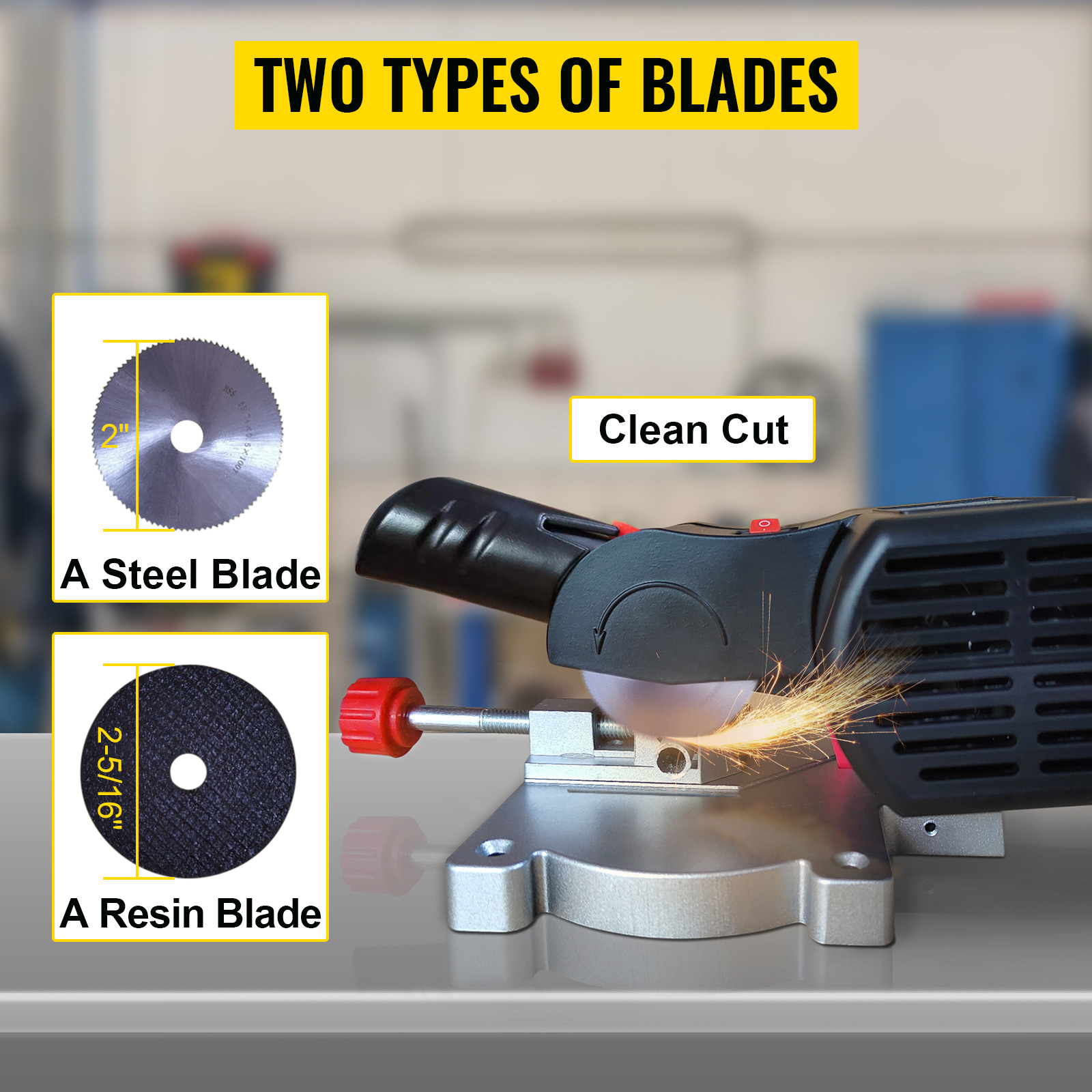

Explore cordless saws for maximum portability and convenience, or choose a table saw for heavy-duty woodworking. Our miter saws are ideal for creating angled cuts, while reciprocating saws provide powerful cutting for demolition work.

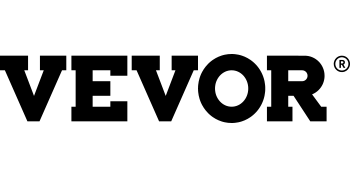

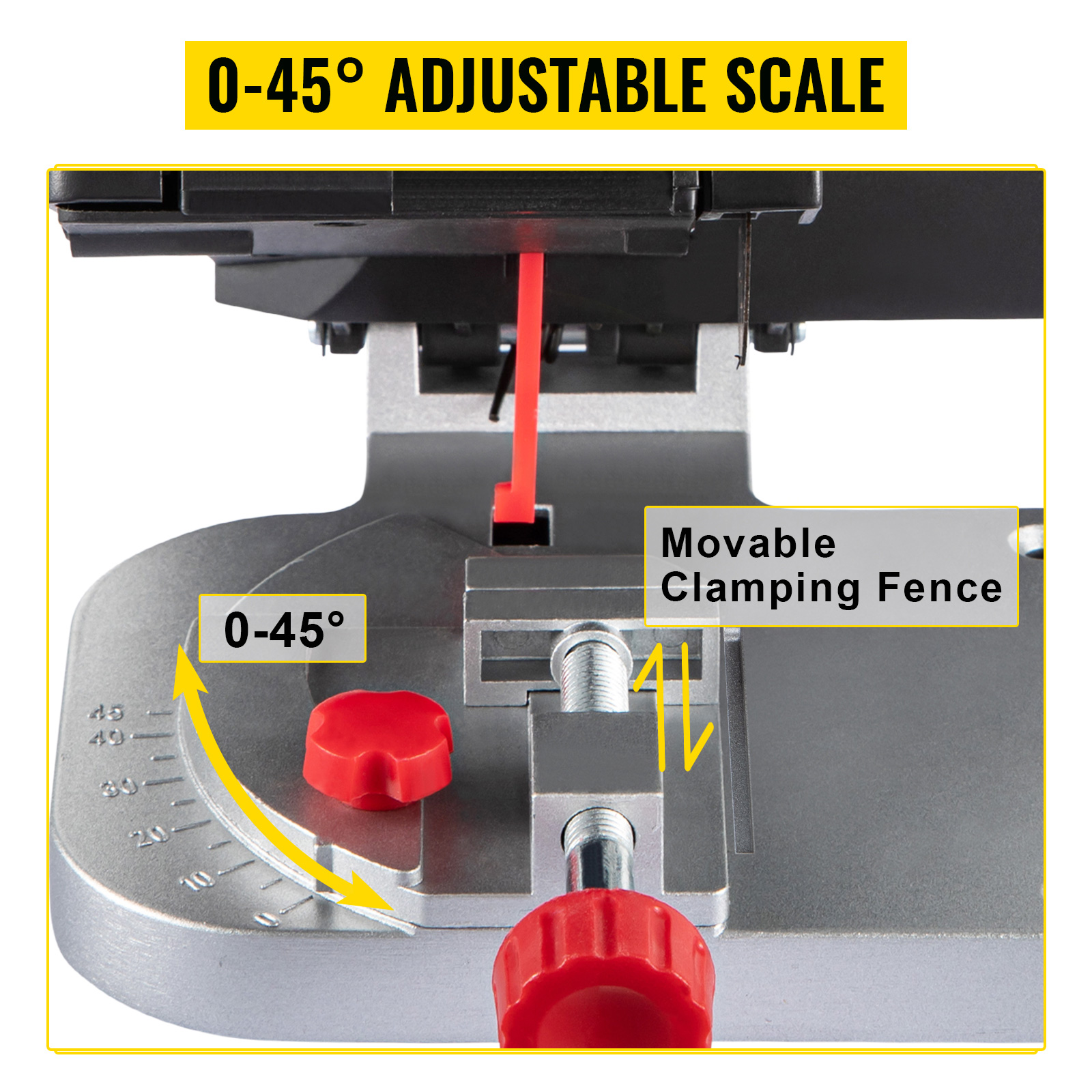

Designed with safety and efficiency in mind, our power cutting tools feature adjustable speeds, ergonomic grips, and long-lasting blades, ensuring precision and control in every cut. Whether you are a professional or a DIY enthusiast, our saws are built to deliver reliable performance.

From power saws to woodworking saws, we offer a range of tools suited for any project. Experience efficiency and precision with top-quality saws built to handle tough materials and deliver clean, accurate results.

Power saws, Electric saws, Cordless saw, Circular saw, Jigsaw, Table saw, Miter saw, Reciprocating saw, Power cutting tools, Saws for woodworking,