Durable Sealing Strip – Perfect for Insulating and Weatherproofing

Best Sealing Strip for Doors, Windows, and Gaps

High-Quality Materials for Long-Lasting Protection

Effective Insulation, Soundproofing, and Draft Prevention

Ideal for Homes, Offices, and Industrial Use

Easy-to-Apply Sealing Strips for Various Applications

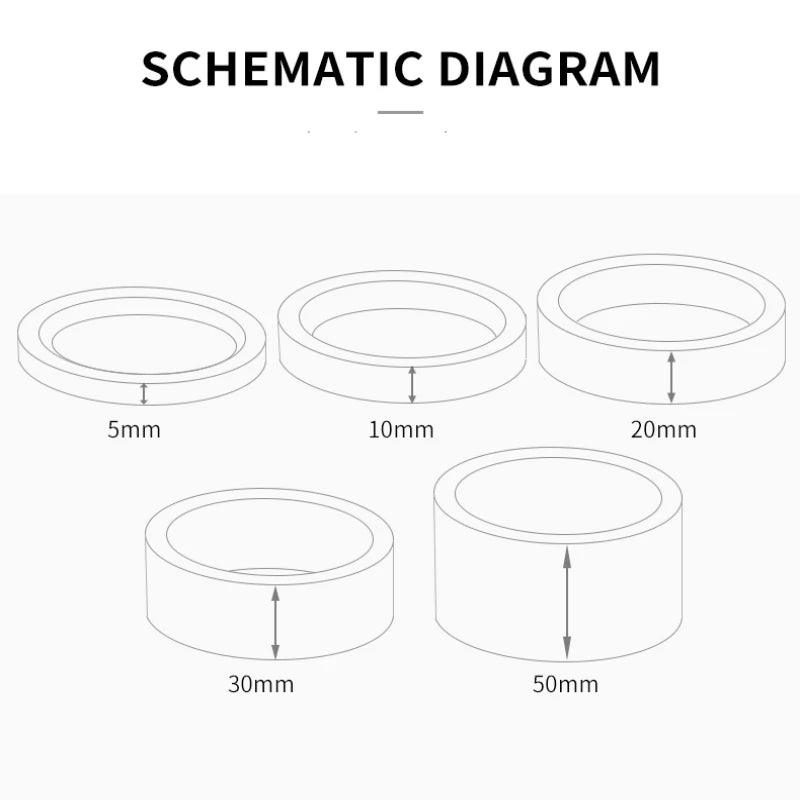

Keep your home or office well-insulated with our sealing strip, designed to provide long-lasting protection against drafts, noise, and weather elements. Our best sealing strip offers a simple and efficient solution for doors, windows, and any gaps that need sealing.

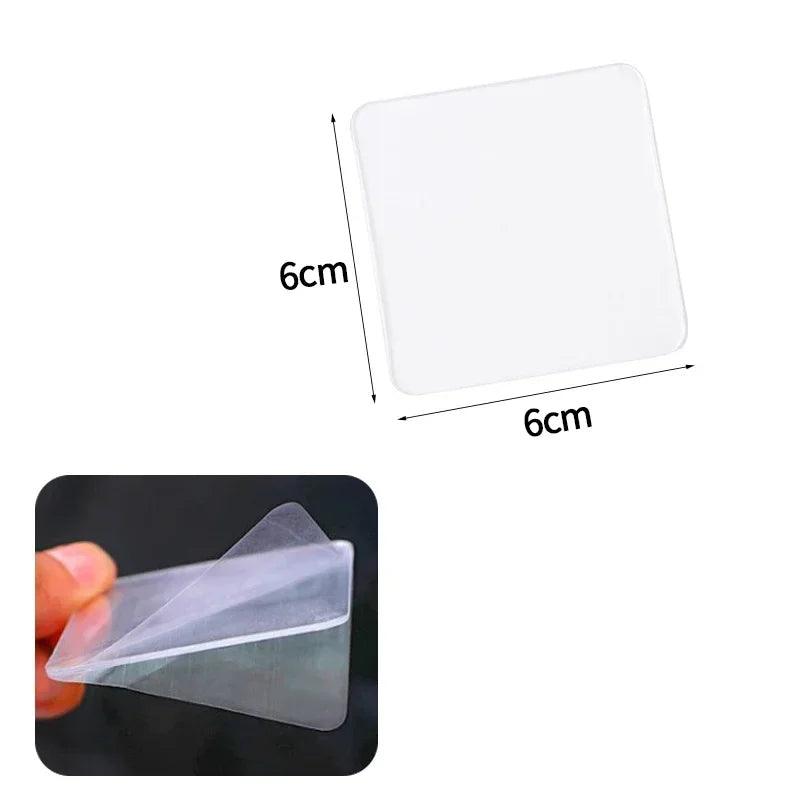

Made from high-quality materials like silicone and rubber, this adhesive sealing strip is easy to apply and creates an airtight seal for superior insulation. Whether you're looking to reduce energy costs or improve comfort, our weatherproofing strip gets the job done.

Our versatile window sealing strip and door sealing strip are designed for a range of applications, from soundproofing to preventing moisture build-up. Ideal for homes, offices, and industrial settings, these strips are the perfect solution for keeping drafts at bay.

Improve your insulation and comfort today with our soundproof sealing strip or opt for our durable silicone sealing strip for long-lasting results. Easy to apply and highly effective, our draft sealing strip ensures a snug fit for maximum protection.

Sealing strip, Weatherproofing strip, Door sealing strip, Window sealing strip, Insulation strip, Adhesive sealing strip, Rubber sealing strip, Soundproof sealing strip, Silicone sealing strip, Draft sealing strip,