Digital Micrometers: The Precision Measuring Tools You Need

In the realm of precision measuring tools, few instruments are as indispensable as digital micrometers. These sophisticated tools have revolutionized the way machinists, engineers, and quality control professionals achieve exact measurements in various applications. With their ability to deliver readings with astounding accuracy, digital micrometers have become the go-to choice for anyone who prioritizes precision.

With a digital display and advanced measuring capabilities, these tools not only simplify the measuring process but also enhance the overall efficiency of tasks at hand. Unlike traditional micrometers, which often rely on mechanical dials and require meticulous manual reading, digital micrometers offer instant feedback, thus reducing the likelihood of human error.

So, why should you be interested in learning about digital micrometers? Understanding how to use digital micrometers effectively equips you with the knowledge to enhance your precision measuring skills. Additionally, regular micrometer calibration is crucial for maintaining accuracy and ensuring that measurements are reliable over time. In this comprehensive guide, we will delve into the world of digital micrometers, exploring their functionality, advantages, and best practices for use.

Whether you are a seasoned professional or a newcomer to the field of engineering and machining, mastering digital micrometers is essential in today's fast-paced environment where accuracy can make or break a project. Join us as we explore the intricacies of these remarkable tools, tips to optimize your measurement techniques, and insights on how to keep your instruments calibrated and functioning at their best.

```

Key Takeaways:

- Digital Micrometer Overview}

- Types of Digital Micrometers}

- Advantages of Digital Micrometers}

- How to Use a Digital Micrometer}

- Maintenance and Calibration}

Digital Micrometer Overview

What are Digital Micrometers?

A digital micrometer is an advanced precision measuring tool designed to measure small distances with high accuracy. Unlike its traditional counterpart, which relies on mechanical components and analog readouts, a digital micrometer uses electronic sensors to provide readings, typically displayed on a digital screen.

The primary purpose of digital micrometers is to ensure precise measurement in various applications, particularly in fields like manufacturing, engineering, and scientific research. These tools help in achieving tighter tolerances, thereby increasing productivity and ensuring quality control in production lines.

Components of Digital Micrometers

A digital micrometer typically consists of several key components that work together to facilitate accurate measurements:

- Main Frame: The structure that holds all components in place, often made of sturdy materials to withstand frequent use.

- Measuring Anvil: A flat surface on which the object to be measured is placed, crucial for contact with the item being measured.

- Moving Spindle: This part moves towards the anvil and is responsible for the precise measurement of the object.

- Digital Display: Shows the measurement reading, allowing for easy interpretation of data, often with options for different measurement units.

- Battery Compartment: Houses the batteries that power the electronic components, essential for operation.

How Digital Micrometers Differ from Traditional Micrometers

Digital micrometers offer distinct advantages over traditional micrometers, making them an ideal choice for many precision measuring tasks. Here are some of the key differences:

- Measurement Readability: Digital micrometers display measurements directly on a screen, eliminating the need for manual reading from a scale, which can reduce human error and enhance measurement consistency.

- Ease of Use: With fewer mechanical parts and the absence of a rotating thimble, digital micrometers are often more user-friendly, especially for individuals new to precision measuring tools.

- Measurement Systems: Many digital micrometers allow users to switch between measurement systems (e.g., metric and imperial) with a simple button press, increasing versatility.

- Memory Functions: Some models are equipped with memory functions that store multiple measurements for later retrieval, promoting better data management in complex measuring tasks.

- Automatic Shut-off: Digital models often come with an automatic shut-off feature, extending battery life by powering down when not in use.

Applications of Digital Micrometers

The versatility of digital micrometers enables their use in a range of applications:

- Manufacturing: Used to check the dimensions of components during production.

- Aerospace: Ensures precise specifications for aircraft components.

- Automotive: Checks tolerances for engine parts and assemblies.

- Research and Development: Utilized in laboratories for precise scientific experiments and measurements.

In summary, digital micrometers represent a significant advancement in the field of precision measuring tools. Their electronic functionality, ease of use, and enhanced accuracy make them indispensable for professionals and hobbyists alike.

Types of Digital Micrometers

Digital micrometers are precision measuring tools that are essential for various applications in machining, engineering, and quality control. Their ability to provide accurate measurements makes them a favored choice for professionals. Below, we explore the different types of digital micrometers available on the market, including their specific applications and essential features.

External Digital Micrometers

External digital micrometers are the most common type used for measuring the outside dimensions of an object. These tools are equipped with a sleek design and a digital display for ease of reading.

- Applications: External micrometers are widely used in mechanical engineering, manufacturing, and in quality assurance processes, where precise measurements of dimensions such as diameter, thickness, and width are essential.

- Features: Most external digital micrometers offer a range of 0-25 mm, 25-50 mm, and up to 100 mm, allowing for flexibility in measurement. They often come with functions such as zero-setting, data-hold, and the ability to switch between metric and imperial units.

Internal Digital Micrometers

As the name suggests, internal digital micrometers are designed to measure the internal dimensions of holes, cylinders, and other recessed spaces. Their construction includes two or more measuring anvils that sit inside an object.

- Applications: These micrometers are particularly useful in verifying the internal diameters of pipes, boreholes, and other cylindrical objects. They are often used in the automotive and aerospace industries.

- Features: Internal digital micrometers can have a range from 0-25 mm or more, with precision levels typically expressed in microns. The digital readouts on these tools also allow for quick measurements without tedious calculations.

Depth Digital Micrometers

Depth digital micrometers measure the depth of holes, slots, and recesses. They generally have a rod-like extension that can reach deep into an object, making it easier to read depth accurately.

- Applications: Commonly used in machining shops and laboratories, depth micrometers help ensure that drilled holes and slots are of the correct depth, which is crucial in assembly work.

- Features: The typical ranges for depth micrometers can include 0-25 mm or 0-50 mm, with a high level of precision. They also often include ratchet stops to ensure consistent pressure while measuring.

Electronic Digital Micrometers

While the above three types are mechanically sound, electronic digital micrometers offer enhanced functionality and convenience. They often feature advanced technology that extends their applications.

- Applications: Primarily used in environments where both accuracy and efficiency are paramount, these micrometers are employed in quality control, laboratories, and precise machining operations.

- Features: Many electronic micrometers offer features such as computer connectivity, allowing users to directly transfer data for record-keeping or analysis. They may also provide additional functionalities like memory storage for multiple readings and calibration adjustment prompts.

How to Use Digital Micrometers

Using digital micrometers is straightforward, but ensuring proper technique is vital for obtaining accurate measurements. Here’s a quick guide to using them effectively:

- Ensure the micrometer is calibrated before use. Most electronic micrometers will alert you if recalibration is needed.

- Place the object you wish to measure between the measuring anvils of the micrometer.

- Gently turn the thimble until you feel resistance to ensure the object is securely in place.

- Read the measurement on the digital display, which will typically show either metric or imperial units based on your preference.

- Record the measurement promptly, as some models may have a data-hold feature to capture the result quickly.

Understanding the different types of digital micrometers enhances the efficiency of precision measuring tasks in various fields. By selecting the appropriate micrometer for your specific application, you open the door to improved accuracy and reliability in your measurements.

Advantages of Digital Micrometers

1. Precision and Accuracy

Digital micrometers excel in providing accuracy in measurements, an essential attribute in industries such as manufacturing, engineering, and quality control. Unlike traditional micrometers, which often rely on interpretation of a scale, digital micrometers present measurements in a clear digital readout, eliminating human error associated with reading scales. This feature is particularly vital when dealing with tight tolerances in precision engineering, where even a slight deviation can result in defective products.

For instance, digital micrometers typically offer resolution down to 0.001 mm or finer. In practical terms, this means that they can measure a part with a precise granularity that enhances overall manufacturing quality. The table below highlights the differences in accuracy among various types of micrometers:

| Type of Micrometer | Resolution (mm) | Typical Use |

|---|---|---|

| Traditional Micrometer | 0.01 | General measurements |

| Digital Micrometer | 0.001 | High precision tasks |

| Electronic Micrometer | 0.0001 | Ultra-fine tolerances |

2. Ease of Reading Measurements

Another significant advantage of digital micrometers is their user-friendly display. The digital readouts are large and easy to read, even in low-light conditions or at awkward angles. Most models have backlit screens, further enhancing visibility. This feature reduces strain on the eyes and allows operators to more quickly assess measurements, ultimately increasing efficiency.

Moreover, because there is no need to interpret a scale, digital micrometers minimize the potential for mistakes. This ease of readability is particularly beneficial for professionals who need to take numerous measurements in a short time span, like technicians in manufacturing environments or inspectors during quality assurance processes.

3. Advanced Data Output Capabilities

In today's technologically-advanced environment, data collection and analysis play critical roles. Digital micrometers are equipped with data output functionalities, allowing users to connect the tool directly to computers or other digital devices for immediate data transfer. This capability enhances productivity by allowing operators to gather and analyze measurement data swiftly. They can also store historical measurement data, making it easier to track product consistency over time.

This feature is especially pertinent in applications where data logging and statistical process control (SPC) are crucial for maintaining product quality. By integrating with software systems, digital micrometers can help streamline workflows, reduce manual data entry errors, and maintain precise records for compliance auditing.

4. Enhanced Productivity in Various Fields

The adoption of digital micrometers in various sectors has demonstrated increased productivity across the board. In manufacturing, their ability to provide accurate measurements with reduced error rates translates to fewer defective parts and less rework. This not only saves time but also reduces material costs, ultimately contributing to the bottom line.

Furthermore, industries such as automotive engineering, aerospace, and electronics are increasingly relying on digital micrometers for their ability to adapt to various measuring applications. Whether measuring the thickness of a wire in electronics or the diameter of a cylinder in engine manufacturing, digital micrometers provide the flexibility needed to accommodate different tasks efficiently.

In conclusion, the myriad of advantages that digital micrometers offer—enhanced accuracy, ease of reading, data output capabilities, and boosted productivity—makes them indispensable tools in today's demanding industrial environments. Whether you're a seasoned engineer or a novice technician, understanding and utilizing digital micrometers can significantly improve your measuring operations.

How to Use a Digital Micrometer

1. Understanding Your Digital Micrometer

A digital micrometer is precision measuring tool commonly used in various industries to measure small dimensions with high accuracy. Before learning how to use it, ensure you understand the components of the device:

- Frame: The main body that holds the internal components.

- Spindle: The moving part used to take measurements.

- Anvil: A stationary part opposite the spindle that supports the object being measured.

- Digital Display: Shows the measurements in the selected units.

- On/Off Button: To turn the device on or off.

- Zeroing Feature: Resets the measurement scale to zero.

2. Setting Up Your Digital Micrometer

To effectively use a digital micrometer, proper setup is essential. Follow these steps:

- Clean the Micrometer: Wipe down the measuring surfaces with a clean cloth to remove any debris or grease.

- Power On: Press the power button to activate the device.

- Select Units: If your micrometer can measure in different units (mm/inches), choose the appropriate setting based on your requirement.

- Calibration: Use a calibration standard to ensure accuracy. Measure the standard and adjust the reading with the zeroing feature if necessary.

3. Measuring Techniques with Digital Micrometers

Here’s a step-by-step approach on how to measure objects accurately:

- Position the Object: Place the item you wish to measure between the spindle and the anvil, ensuring it is stable and correctly aligned.

- Close the Spindle: Gently turn the ratchet or knurled thumb screw until the spindle contacts the object. Avoid over-tightening, which can lead to inaccurate readings.

- Read the Measurement: Observe the digital display for the measurement. Note the reading when it stabilizes.

- Repeat Measurements: For precision, take multiple measurements and calculate an average. This minimizes errors caused by environmental factors.

4. Tips for Ensuring Accurate Readings

Maintaining the accuracy of your measurements is crucial. Here are some tips:

- Environment: Use the digital micrometer in a controlled environment to minimize temperature fluctuations that can affect accuracy.

- Humidity Levels: Ensure that humidity levels are within a suitable range to prevent corrosion or deformation of the tool and the measurement objects.

- Regular Calibration: Schedule regular calibration of your micrometer to maintain its precision as per industry standards.

- Storage: Store the micrometer in a protective case to prevent damage when not in use.

5. Common Mistakes to Avoid

Being aware of common pitfalls can help enhance the longevity of your digital micrometers and improve the accuracy of your work:

| Common Mistake | Description |

|---|---|

| Neglecting Calibration | Failing to calibrate can lead to significant measurement errors. |

| Inconsistent Pressure | Applying uneven pressure can distort readings. |

| Not Accounting for Expansions | Ignoring temperature effects on materials being measured can result in inaccurate dimensions. |

6. Maintaining Your Digital Micrometer

Finally, proper maintenance is essential for the longevity of your micrometer:

- Regular Cleaning: After each use, clean the measuring surfaces with appropriate materials.

- Battery Checks: Monitor your battery levels and replace them as needed to avoid interruptions in functionality.

- Software Updates: If applicable, keep the built-in software updated to enhance performance and accuracy.

Maintenance and Calibration

Understanding Digital Micrometers

Digital micrometers are precision measuring tools used extensively in various industries to measure the thickness or diameter of small objects with utmost accuracy. Given their sensitivity and the crucial role they play in precision tasks, maintaining and calibrating these instruments is paramount. Regular maintenance ensures their longevity while calibration guarantees that measurements remain accurate over time.

Importance of Regular Maintenance

Implementing a regular maintenance schedule for your digital micrometers is essential to prevent wear and tear. Here are some best practices to follow:

- Keep the Micrometer Clean: The most effective way to maintain the functionality of your digital micrometers is to keep them free from dirt, oil, and other contaminants. Use a soft cloth and suitable cleaning agents recommended by the manufacturer to wipe down the external surfaces.

- Avoid Physical Damage: Store your micrometer in a protective case when not in use. Avoid dropping them or exposing them to harsh environments to prevent calibrations from shifting.

- Regular Inspection: Conduct routine inspections to check for any signs of wear, corrosion, or component failure. Catching these issues early can save you from costly repairs or replacement.

Calibrating Your Digital Micrometer

Calibrating your micrometer is vital to ensure accurate measurements. While the specifics can vary based on the model, the general procedure can be summarized as follows:

- Acquire Calibration Standards: You will need a set of reference standards that are accurately measured and certified. These should ideally be traceable to a national standards body.

- Temperature Control: Ensure the calibration is performed in an environment with a stable temperature, as fluctuations can affect measurement outcomes.

- Zero Calibration: Before measuring, ensure the micrometer reads zero. This may require adjustment if the instrument is not showing default readings when fully closed.

- Verification: Use your standards to measure and confirm that the micrometer’s readings match the expected values.

Best Practices for Calibration

Here are some tips to ensure effective micrometer calibration:

- Frequency of Calibration: Depending on usage, calibrate your digital micrometers at least once every six months. High-frequency users may want to consider monthly calibrations.

- Documenting Calibration: Always maintain a log of calibration dates, methods used, and any adjustments made. Documentation is crucial for quality control and compliance.

- Consider Professional Help: If in doubt, engage a professional to perform the calibration. This ensures adherence to industry standards and accurate results.

Tips for Using Digital Micrometers

Knowing how to use your digital micrometers correctly can also contribute to their maintenance.

- Proper Handling: Always handle the micrometer gently. Avoid applying excessive force when closing the jaws down to avoid misalignment.

- Battery Care: If using electronic micrometers, ensure the battery is regularly checked and replaced when low. Keeping the battery in optimal condition can prevent malfunctioning.

- Choosing the Right Micrometer: Depending on the applications you are undertaking, always choose the right type of micrometer to suit your needs whether it’s a digital micrometer or another style.

Conclusion

The precision of measurements provided by digital micrometers can only be achieved and maintained through diligent care and regular calibration. Following the best practices outlined above ensures that your micrometer remains a reliable tool for all your precision measuring needs. Invest time and resources in maintaining your instruments, and you will reap the benefits in terms of accuracy and longevity.

Conclusion

In summary, digital micrometers are indispensable tools for achieving precision in various applications, from manufacturing to scientific research. By employing micrometer calibration, users can ensure their measurements are accurate and reliable. Mastery of how to use digital micrometers effectively not only enhances the quality of work but also boosts overall efficiency.

As we have explored, electronic micrometers provide a distinct advantage in terms of ease of reading and automated data recording. The integration of such precision measuring tools into routine measurement tasks signifies a commitment to quality and performance excellence. Whether you are a seasoned professional or a beginner, understanding the intricacies of digital micrometers will empower you to achieve exceptional results.

In closing, we encourage you to further reflect on how you can incorporate digital micrometers into your work processes. Consider investing in quality tools, enhancing your knowledge through continuous learning, and sharing your insights with fellow professionals. Your pursuit of precision starts today – take that next step!

FAQs

What is a digital micrometer?

A digital micrometer is a precision measuring tool used to measure small distances with high accuracy. It employs electronic sensors to provide a digital readout of measurements.

How do I calibrate a digital micrometer?

To calibrate a digital micrometer, you can use calibration standards, such as gauge blocks, to ensure the micrometer's readings are accurate. Follow the manufacturer’s calibration procedure as outlined in the manual.

What are the advantages of electronic micrometers over traditional ones?

Electronic micrometers offer easier readability with digital displays, automatic shut-off features, and the ability to record and store measurements electronically, enhancing precision and convenience.

How do I use digital micrometers correctly?

To use a digital micrometer correctly, ensure the anvil and spindle are clean, gently close the micrometer around the object, and read the measurement on the digital display without applying excessive force.

What are some common applications for digital micrometers?

Common applications for digital micrometers include manufacturing, mechanical engineering, precision machining, and scientific research, where accurate measurements are critical.

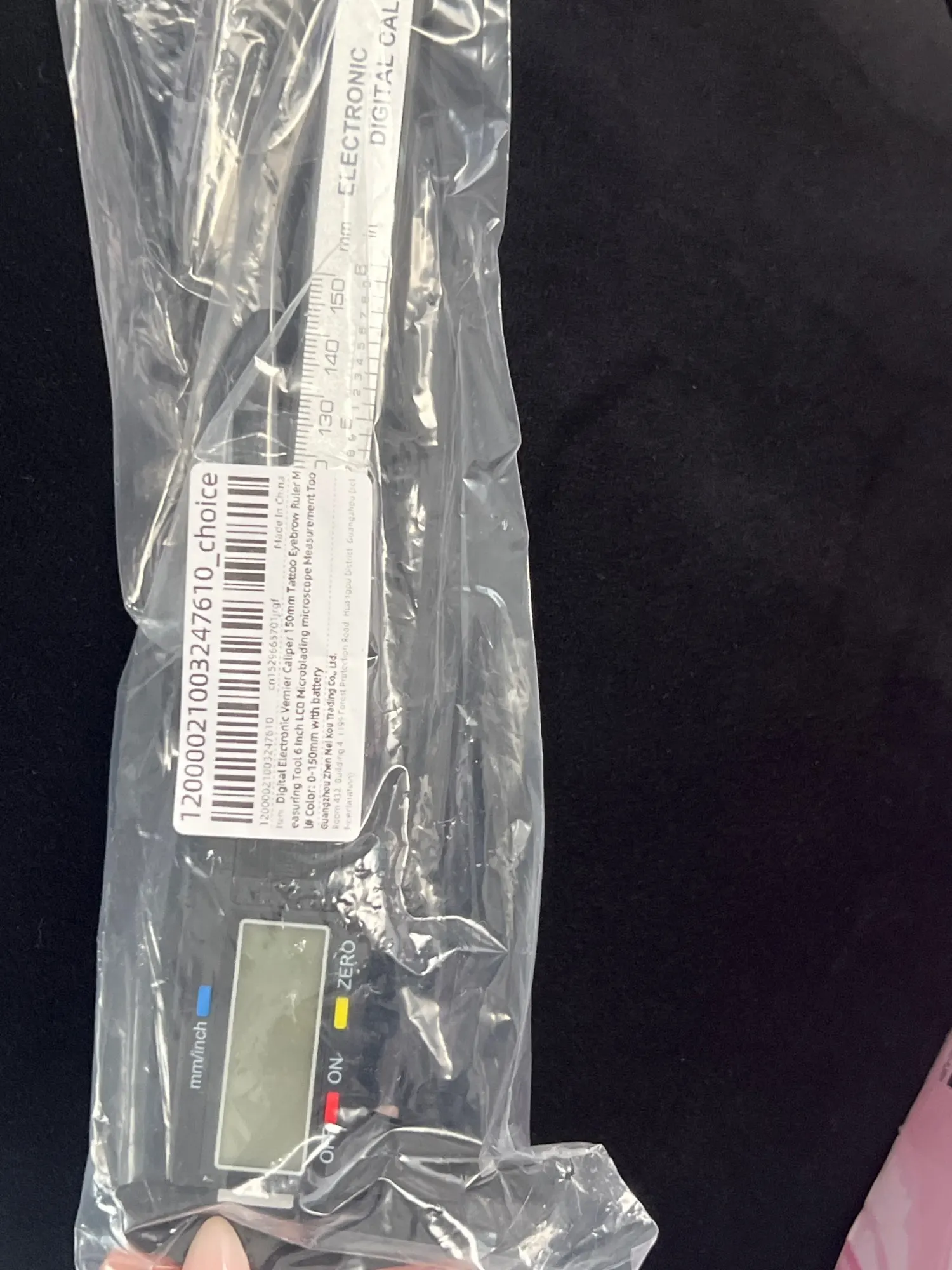

Digital Micrometers: Accurate Measurements Made Simple

Achieve unmatched precision with our premium range of digital measurement instruments. Designed to elevate your measurement capabilities, our selection includes the best in digital micrometers and electronic calipers.

Our Premium Collection Includes:

- Digital Micrometers: Ensure pinpoint accuracy in every measurement with our high-quality digital micrometers, perfect for both professional and personal use.

- Electronic Calipers: Complement your micrometers with electronic calipers that offer seamless digital readings and enhanced efficiency.

- Vernier Calipers: Get reliable measurements with our traditional yet effective vernier calipers, available in both manual and digital formats.

- Micrometer Gauges: For those who need versatile measurement tools, our micrometer gauges deliver accuracy and ease of use.

Why Choose Our Instruments:

- Cutting-Edge Technology: Experience the future of measurement with our advanced digital verniers and electronic micrometers that eliminate manual errors.

- Precision and Accuracy: Achieve flawless results effortlessly with our top-of-the-line equipment designed for superior accuracy.

- Professional and Novice Friendly: Whether you're a seasoned professional or a novice enthusiast, our selection caters to all levels of expertise.

Elevate your precision game and trust in the accuracy of our advanced digital measurement instruments. Shop now and transform the way you measure with confidence.